“The duration of COVID-19 and the level of ensuing deaths and chaos it leaves in its wake will determine to some degree the way that supply chains evolve, but the havoc that this global pandemic is already wreaking on manufacturing, retail, and society at large will have effects that will remain long after the coronavirus — this version of it, at any rate — has come and gone.”

-Supply chain in the post COVID era, IDC

COVID 19 has changed the face of businesses forever. Every industry has been hit hard by the global challenge, and organizations across are working at an unprecedented pace to mitigate current risks and defend themselves against future disruptions. The past couple of months have increasingly exposed key supply chain vulnerabilities of organizations- disconnected supply chain planning systems, sub-optimized inventory strategy, and poor supplier communication. These have created a domino effect with higher stockout rates, skewed partner priorities, ineffective business decision-making, and even lower productivity of key business functions such as Finance, Sales, HR, etc. Determined to overcome the substantial business and operational upheavals, organizations are now finally analyzing their supply chains and taking restorative measures. Here we list down some of the outcomes of the renewed approach to supply chain management:

Gaining prominence of Supply Chain Governance and Security

The pandemic has forced enterprises to move operations to multiple geos for low-cost production, resulting in an increased awareness of macro trends, global risk events and security incidents. Modern supply chain approaches are increasingly incorporating the impact of politics and international policies and putting in place strong governance mechanisms to ensure the right amount of oversight on the supply chain process and allay future disruptions.

Supply chains driven by Connected Planning

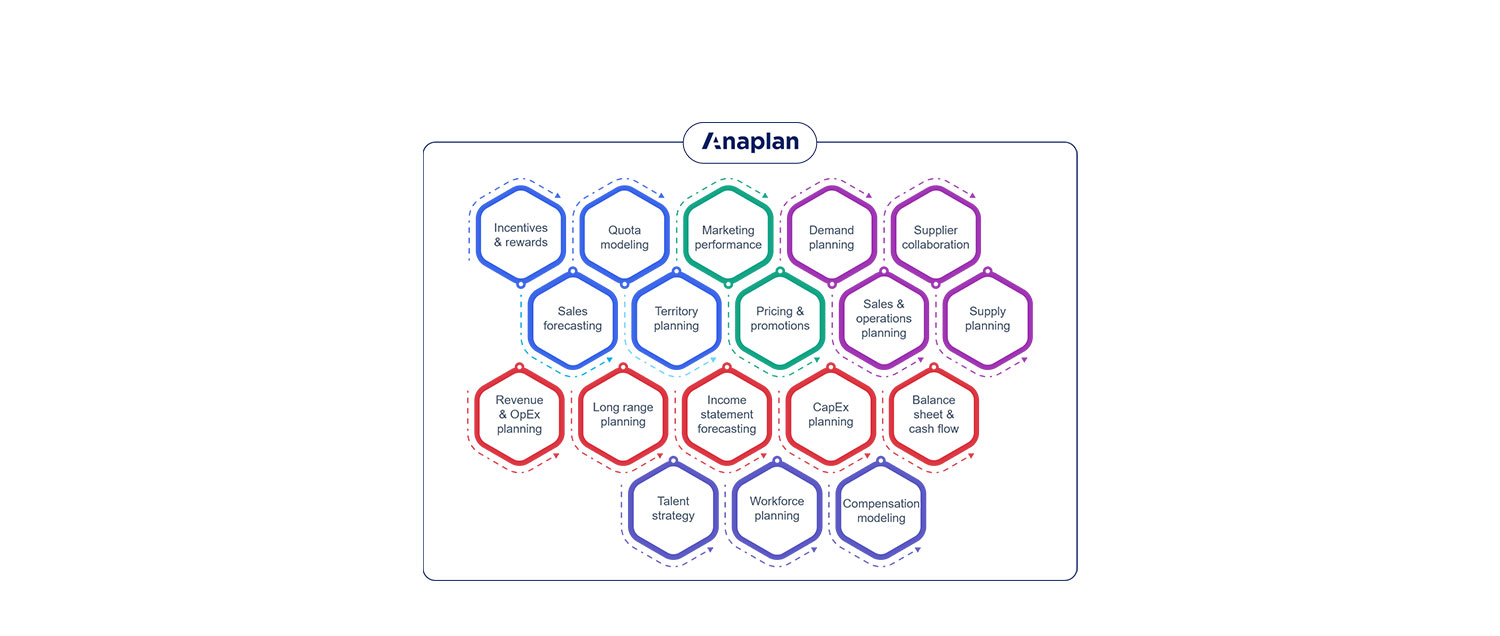

The current pandemic has brought into focus the heightened need for supply chain resiliency. In a bid to build stronger long-term operations, organizations are replacing disparate spreadsheets, standalone systems, and disconnected point-to-point solutions, with a single cohesive solution that combines processes across Finance, Sales, Supply chain, Marketing and HR, for quicker and better decision-making.

In such an integrated business planning approach, organizations can quickly adapt to changing market conditions and business priorities, enabled by the end-to-end visibility into supplier historical performance as well as needs and goals of internal business units and processes. A unified platform from Anaplan that enhances internal collaboration are leading to highly agile supply chains.

Better preparedness with Ecosystem Partners

For enterprises evaluating supply chain technology and solutions, the right guidance on how to re-assess supply chain stability, how to introduce and select a pilot, how to enable connected planning across the organization, etc is vital for supply chain success. This is where ecosystem partners come in, helping organizations do all these as they adapt to the new normal with a robust supply chain that delivers new levels of productivity, quality and service.

Case in point

Let us take the case of a global, US based beverage company who had to transfer their bottling plants to 70 independent companies. Managing the diverse product categories, with 100 new SKUs launched in a year and maintaining 300-tab spreadsheets for every product launch was becoming a major challenge. In addition, the company also had to adhere to stringent technology implementation timelines.

Taking a connected planning approach, the global enterprise partnered with a supply chain experts from Solvanni to align procurement activity leveraging a common platform. The solution brought together multiple components such as Supplier Collaboration for direct materials procurement, Product Cost management, Pricing Optimization, Long-Range planning, CAPEX, Revenue & OPEX, Income Statement Forecasting and finally Demand, Sales & Operations Planning. By facilitating end-to-end supply chain visibility, they were able to roll-out forecasts for seventy new products in just three months. Enabling 150+ users at 68 bottlers to submit forecast data, the robust processes and timely communications have strengthened the supply chain and minimized supply disruptions.

Future supply chains

Manufacturing companies across automotive, engineering, manufacturing, healthcare, industrial and consumer goods sectors are now investing heavily in technology and partnerships to transform entire supply chains. The new world supply chains are highly resilient and sustainable and take into account multiple dimensions of socio-political conditions. Trade wars, global politics and national policies are now essential considerations of supply chain structures of the future. And so are service providers like Solvanni who can scale up aggressively to meet the ever- evolving demands and react quickly to change.