Season’s Greetings! Brought to you by Solvanni

It is that time of the year again; and the retail, consumer goods, F&B, and logistics industries are eagerly waiting for consumers to splurge, despite the recent dip in global economies. It is also the most dreaded time for supply chain leaders across the globe, all except Santa. He’s probably the only supply chain leader who not only knows when you’ve been good or bad, but his demand forecasting system works so well that everyone receives their presents on Christmas day, every time! But for lesser mortals, this isn’t the time be bogged down by glitches, human or technical. Most CXOs would remember candy giant Hershey’s horrific Halloween of ’99 when they could not deliver $100 million worth of Kisses and Jolly Ranchers. No one would want to get caught in a spot like that. *

A recent survey by Deloitte indicated that 65% respondents preferred online shopping to avoid crowds. While this doesn’t come as a surprise in the current times, this holiday season will be a witness to new challenges and roadblocks as organizations bravely prepare to meet the demand surge. Especially when most global sourcing, manufacturing, transportation, and last mile delivery organizations are not out of the rut yet. In light of the new supply chain challenges, on-time delivery will see a new low. Salesforce predicts that 700 million gifts will not arrive in time for the holidays.

The dynamics of Demand Planning

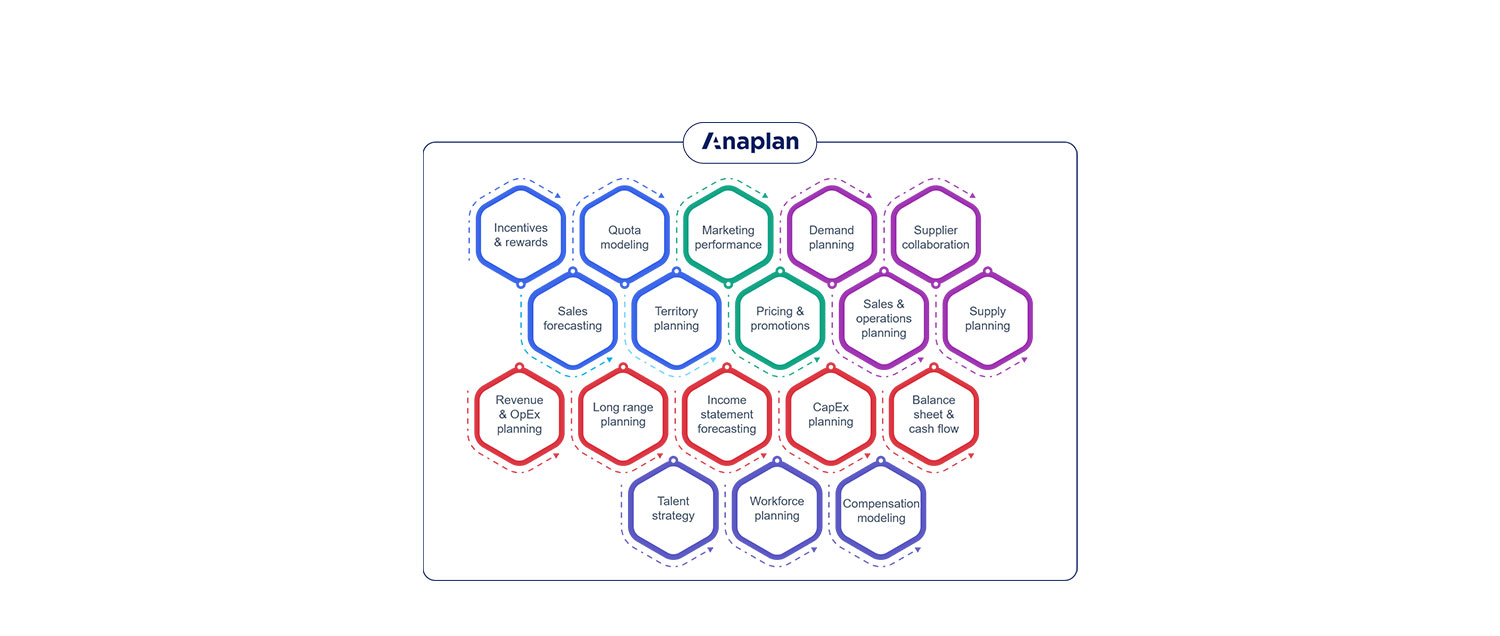

Demand planning has never been an easy job. Planners have to factor in a lot of variables, coordinate across business key business functions of Sales, Marketing, HR, and Finance, understand demand patterns and market conditions that impact those patterns. Successful demand planning demands being proactive and prepared for dynamic markets shifts, such as the impending holiday season. All of these are possible only when there is a free flow of information across the organization. There are several tools in the market that leverage historical data to generate market forecasts. However, the biggest challenge with most is their inability to deliver accurate forecasts in case of unforeseen market/economic conditions such as the current situation. Let us look at three key attributes of a demand planning tool that are critical in the current times.

- Address multiple types of datasets

Many commonly available forecasting tools generally use a single type of data, which is in most cases enough to deliver a forecast. Some new tools can compute with multiple types of data, delivering a more accurate prediction. Additional data sets can help create more customized forecasts, applicable to specific scenarios, with continuously improving accuracy of the forecasts, much needed to manage demand efficiently during the holiday season.

- Run ad hoc analysis

Almost all forecasting systems available today provide an accurate picture of the future. But there are only a handful of tools that can delve into the drivers that result in a particular prediction. The ability to run such ad-hoc to perform analysis on your data is a powerful mechanism to analyze the forecast from multiple angles and thoroughly study the drivers that have the most impact on the forecast outcome.

- Democratize forecasting

Analytics and Machine Learning (ML) have traditionally been viewed as the stronghold of data scientists and experts with special degrees. An innovative forecasting model should be able to drive AI & ML capabilities across the organization while enhancing the efficiency of the specialists at the same time. Such a tool democratizes ML forecasting, providing quick and easy access to the insights to whoever needs it within the organization, thus empowering more people to drive value and handle seasonal spikes with ease.

Powering order fulfillment beyond 2020

It is not just Santa who needs an effective demand planning mechanism; accurate forecasting is a must for successful supply chain dynamics. We will see more uncertainty in the times to come with strained geopolitical relations and economic instabilities. Resilient supply chains and empowered leaders with strong decision-making capabilities will leverage technology to drive real business outcomes in the future of successful demand planning.